Thank you for considering JSD Pressworks for your printing and embroidery needs. This Frequently Asked Questions page is meant to be a reference and general explanation for some of the processes we use, how they are applied, key points and requirements of the process, and how it might alter your image when applied.

Got a design already that you want printed? Great! Send us an email with your art files and what you are looking to use it for. Whether printing on shirts, embroidering on hats, printing up stickers, or any other service we offer. We'll make sure the art works for the applications we are looking at and decide on garments/colors.

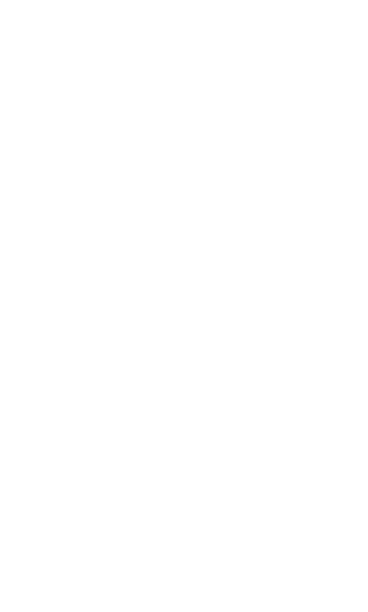

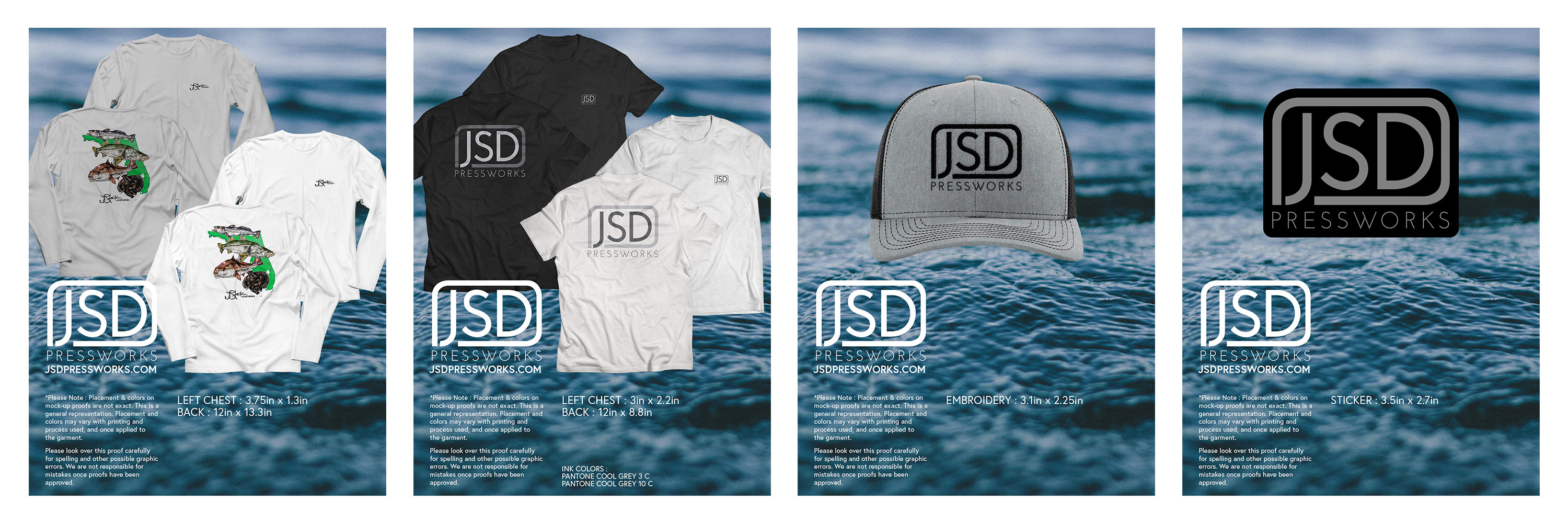

In the process of setting up print files, we'll put together a mock-up to give you a general sense of the final product (since some processes can change art appearance when applied to certain garment colors) and lock-in color, sizing, and make sure the art is correct before printing. Then we take a deposit, get everything on order. Soon enough you'll be getting your new gear! Below are some examples of mockups.

Don't have a design already, but have a good sense of what you are looking for? We offer design services as well. We can build shirts from your logo, including any additional info you want to add. Create custom patch designs. Build custom boat drawings of your vessel. Plus help with a range of other design needs.

While we use high-quality printing techniques, we can only print as well as the artwork we have to print with. We ask that whenever possible, you provide the best quality files you can. Vector files are preferred when available. In many cases high quality image files will also work. Files designed for the web or social media are often low-quality for printing purposes, and can either end up with additional costs to reproduce it properly, or with a sub-par print.

We generally prefer .AI / .EPS / .PDF files, but high resolution .JPG and .PNG files can also work.

We offer a range of printing process at JSD Pressworks. Each process has it's strengths, but also has it's limitations. For printing on garments, we offer Sublimation, Silkscreen, and Direct-to-Garment processes. We go into detail on each process further down, but first here is a simple breakdown of the requirements for each process:

Process: For sublimation, we print your art on a specialized paper with specialized ink. That paper is placed in a heat press with a shirt. The heat turns the ink into a gas, which embeds into the shirt material. We repeat this process for every 'hit' on a shirt; ex- once for the left chest, once more for the back.

Results: The benefits of this process is the art is embedded into the fabric of the garment. It's not washing out. And the garment feels no different where the art is applied.

Key Points: This process only works on garments that are primarily polyester. The most common example would be performance shirts (microfiber sun shirts). 65% Polyester / 35% Cotton t-shirts are also a popular option for this process.

-Due to the process of sublimation, the color of the garment becomes the lightest color in your design, there is no way to print white ink. Thus the garment color can greatly alter the final art appearance. Sublimation works best on lighter color garments. Below are some representations of artwork sublimated on various garment colors.

-Due to the process of sublimation, the color of the garment becomes the lightest color in your design, there is no way to print white ink. Thus the garment color can greatly alter the final art appearance. Sublimation works best on lighter color garments. Below are some representations of artwork sublimated on various garment colors.

This means sublimation cannot be used for printing a light design on a dark shirt, for example - a white logo on a navy shirt. This would have to be achieved through silkscreen or cut-and-sew (for larger runs).

Cut-and-sew is a special option for larger sublimation runs. With this process, we make a special order and your designs are sublimated onto the fabric before the shirts are made, then they are cut and sewn together as normal.

This option is ideal for shirts that have many print placements, and for having light art with a dark garment color. Since your art and the garment color are sublimated at the same time, there is no change to your artwork's appearance.

Process: With Silkscreen printing, your art is applied via ink mechanically pressed through screens with stencils photographically applied of your art. Each color is seperated onto a different screen, each applied one after another on the shirt.

Results: With this process, the ink sits on top of the garment. You can feel the ink where applied and adds a bit of stiffness to the fabric. How much so depends on how much your art covers the garment. Ink is heat-treated and long-lasting, staying on garment after many washes.

Key Points: Silkscreen can be used with a wide variety of garments, including performance (microfiber) shirts and a range of t-shirt blends.

-Silkscreen is ideal for artwork with limited colors. Most of our runs have from 1-3 colors in their art.

-Silkscreen is the option for printing on darker garments. Want to print your logo in white on a black t-shirt? Silkscreen is your answer. Below are small sampling of the wide range of applications for silkscreen printing.

-Printing on a dark color garment requires a white underbase layer to first be printed. This ensures the ink colors are true and unaffected by the garment color beneath. This means a 3-color art on a dark shirt is a 4-color print job

Process: Direct-to-Garment (DTG) printing can best be described as running the shirt through a large, specialized inkjet printer, which directly applies your art. The shirt is then heat treated to set in the art permanently.

Results: With DTG printing, the ink is absorbed by the cotton shirt and becomes embedded into the fabric. The garment feels no different where the art is applied.

Key Points: DTG printing only works on cotton shirts, or shirt blends that are majority cotton. 100% cotton or 90% Cotton / 10% Polyester (the typical Athletic Heather shirt) are preferred.

-Due to the process of DTG printing, the color of the garment becomes the lightest color in your design, there is no white ink in our process. Thus the garment color can greatly alter the final art appearance. DTG printing works best on lighter color garments. Below are some representations of DTG prints on various garment colors.

This means our DTG prints cannot be used for printing a light design on a dark shirt, for example - a white logo on a navy shirt. This would need to be achieved through silkscreen.

Aside from printing, we also offer embroidery services. This process is a great way to add your logo to a hat, or create custom polos for your business. Email us the logo you are looking to stitch out, and once we determine it will work, we'll work up a mock for sizing and color choice. Once approved, we'll create a digitized file (a special file that tells the embroidery machine how to stitch your art). Best results are generally with a limited number of colors per design. The majority of designs we embroider have 1 to 3 colors total.

Patches are a great alternative to embroidery on hats. Patches themselves have their own charm and aesthetic, but they also are a great option for applying full color artwork to hats. While there is a bit of delay between ordering patches and getting them in, the added benefit is that you can order them in large batches which we can keep on hand for fill-on orders down the road.

Sticker terminology can be tricky since certain terms are used interchangeably while discussion different products.

We offer two types of stickers. By far our most popular is the printed sticker. This is the option if you want your logo or design in a full color, but works well with single color logos as well. The art is printed on sticker material, then the plotter cuts it out with backing included. And you end up with a stack of stickers.

Our other option are vinyl decals. These are for single color designs only. And the process requires vector artwork. With this process, we run a roll of vinyl through the plotter. Then we must go through and pull out the excess vinyl by hand, revealing your art. We then apply tape over the sticker, which will be used to apply the sticker when used. The benefit of this process is you effectively get a transparent sticker, since there simply is only vinyl for your design, and nothing else. This process allows us to run large stickers, for say business information on the door of a work truck or FL numbers on the side of your boat.